How to Specify a Cartridge Heater From Your Heater Manufacturer

Factors that Impact the Longevity of a Cartridge Heater

Considerations to Maximize the Lifespan of Your Cartridge Heater

As a manufacturer of electrical process heaters, we understand that cartridge heaters are critical components in ensuring the efficiency and reliability of your operations. Cartridge heaters, known for their high watt density and precise heating capabilities, play a vital role in applications requiring consistent and high heat. However, their longevity can be affected by several, often controllable, factors. Today we’re discussing these factors, along with changes to consider to maximize the lifespan of your cartridge heaters.

critical components in ensuring the efficiency and reliability of your operations. Cartridge heaters, known for their high watt density and precise heating capabilities, play a vital role in applications requiring consistent and high heat. However, their longevity can be affected by several, often controllable, factors. Today we’re discussing these factors, along with changes to consider to maximize the lifespan of your cartridge heaters.

Key Factors Affecting Cartridge Heater Longevity

Operating Temperature

Impact: High operating temperatures can significantly reduce the lifespan of a cartridge heater. Continuous exposure to temperatures near or beyond the heater’s rated capacity can lead to rapid degradation.

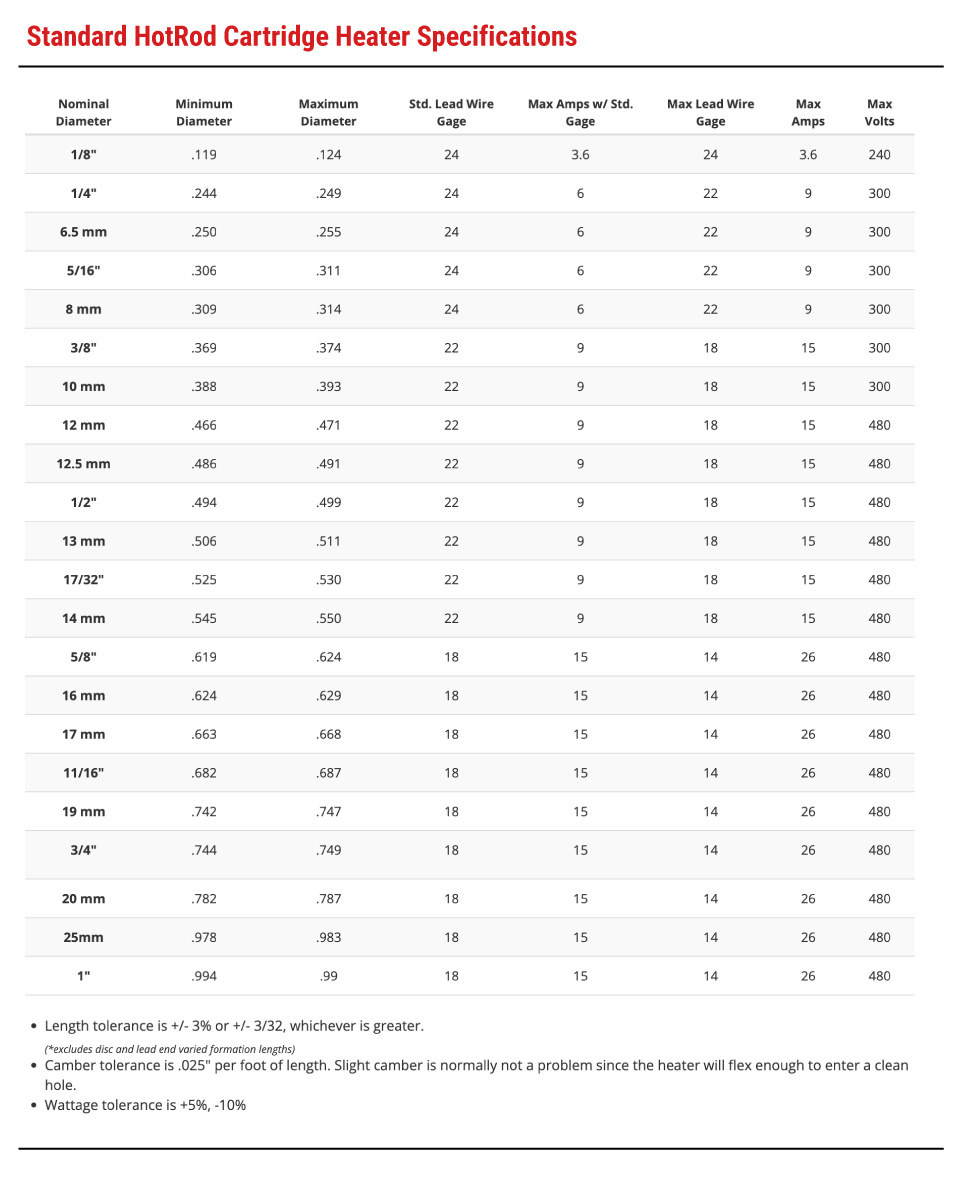

Consideration: Ensure that the cartridge heater’s temperature rating matches the application requirements. Where possible, operate below the maximum rated temperature to prolong life. This step needs to start at the design phase to verify a heater is the correct one for the application. Always check your controller proportional-integral-derivative (PID) settings to ensure set points do not exceed the temperature rating of the heater. At the same time, you will want to check to make sure temperature sensors (thermocouples and resistance temperature detectors—RTDs) are located, installed, and wired correctly to provide accurate feedback to the temperature control system. Another overlooked factor here is the rating of the leadwire themselves; deterioration of the lead wires will lead to a shortened life of the heater as well.

Consideration: Ensure that the cartridge heater’s temperature rating matches the application requirements. Where possible, operate below the maximum rated temperature to prolong life. This step needs to start at the design phase to verify a heater is the correct one for the application. Always check your controller proportional-integral-derivative (PID) settings to ensure set points do not exceed the temperature rating of the heater. At the same time, you will want to check to make sure temperature sensors (thermocouples and resistance temperature detectors—RTDs) are located, installed, and wired correctly to provide accurate feedback to the temperature control system. Another overlooked factor here is the rating of the leadwire themselves; deterioration of the lead wires will lead to a shortened life of the heater as well.

Watt Density

Impact: High watt density can lead to hotspots and uneven heating, which can cause premature failure. Operating the cartridge heater at power levels higher than its design specifications can lead to overheating and failure. Adhering to the recommended power ratings is crucial.

Consideration: Choose a cartridge heater with an appropriate watt density for your application. Electrical process heaters in general perform their best when the design allows for adequate spacing between the resistance wire along the heated area. If spacing is too close, short circuits happen which lead to a sudden surge in the current flow and damage to the resistance wires.

Installation Technique

Impact: Improper installation, such as inadequate fit in the bore or insufficient heat transfer medium, can cause uneven heating and thermal expansion, leading to damage. As well, physical damage from mishandling, vibration, or other mechanical factors can impact the integrity of the heater and reduce its lifespan. Proper installation and handling procedures are essential.

Consideration: Ensure that the cartridge heater fits snugly within the bore. Use thermal grease or other heat transfer media to promote even heat distribution and reduce thermal stress. Ensure correct installation according to manufacturer guidelines to prevent mechanical stress and damage. Heaters will always be slightly smaller than the nominal process hole diameter to ensure ease of installation, but then expand to make proper contact with the process hole walls. A handler will also want to allow adequate time for the heater to cool prior to attempting to remove.

Environmental Conditions

Impact: Harsh environments, including exposure to moisture, chemicals, or vibrations, can affect heater longevity. As an example, slight amounts of moisture can impact the performance of the cartridge heater. Over time, and if stored in a high humidity environment, the heater can get small amounts of moisture in it. If there is a moisture-related failure, it will most often be seen through perforations or holes in the sheath of the heater, as the moisture is trying to escape the heater body.

Consideration: Select cartridge heaters with protective coatings or seals if they will be exposed to corrosive environments or moisture. If moisture is suspected, employ a “soft start/bake out” stage of your start up process: perform a soft start to slowly bake out any small amounts of moisture that may be in the heater as part of any start up process. Additionally, ensure that the heater design accounts for potential vibration.

Electrical Issues

Impact: Voltage fluctuations, power surges, and electrical noise can cause insulation breakdown and reduce heater life. Variations in voltage can cause excessive heating or premature failure of the cartridge heater. Ensuring a stable power supply or using voltage regulation devices can help prevent this.

Consideration: Utilize power conditioning devices such as surge protectors and voltage regulators to ensure stable electrical supply. Regularly check and maintain electrical connections. A silicon-controlled rectifier (SCR) can be used to limit the voltage and current.

Changes to Consider for Improved Longevity

Double Down on Temperature Controls

We spoke to this above, and it is important to reiterate here. Use temperature control devices to maintain the heater within its specified operating range and avoid thermal shock. Start by checking all PID settings. You can also adjust power control methods. An SCR power controller will provide the most responsive control over the heater and limit mechanical strain. It’s also always important to check that the temperature sensors (often thermocouples and RTDs) are in good working condition and close enough to the heater(s) to provide an accurate temperature signal.

Advanced Materials and Coatings

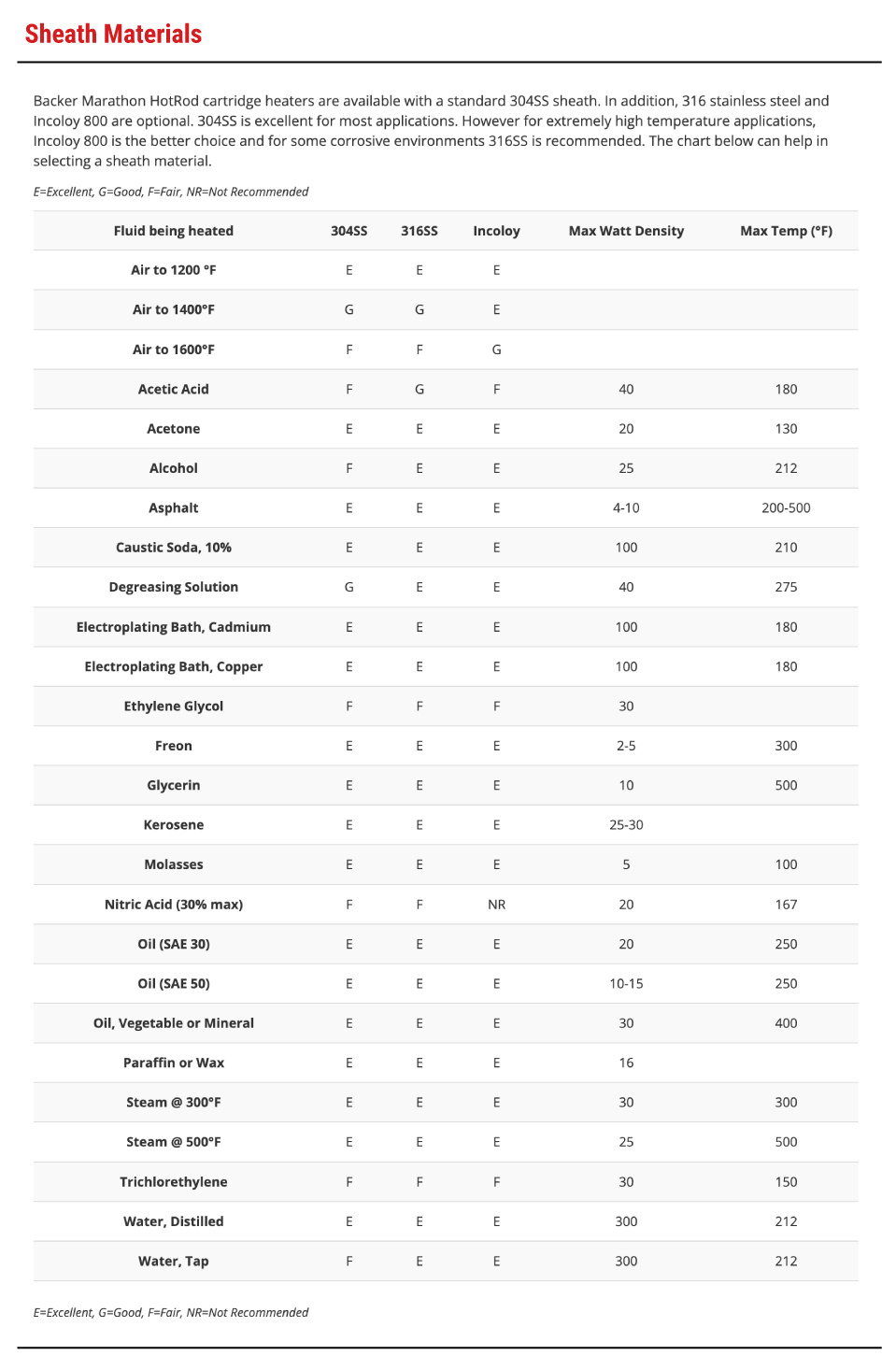

Consider upgrading to cartridge heaters made with advanced materials, such as Incoloy or stainless steel, which offer better resistance to oxidation and corrosion.

Enhanced Design Features

Incorporate design improvements such as internal thermocouples for precise temperature monitoring, or swaged construction, which improves heat transfer and durability by reducing air gaps. Distributed wattage is another design enhancement. Through this design, it’s possible to assign more resistance to the outside of the dies and platens to offset the impacts of heat sink on the process.

Regular Maintenance and Monitoring

Implement a regular maintenance schedule to inspect cartridge heaters for signs of wear and tear. Periodic inspection and maintenance can help identify potential issues early and prevent catastrophic failures. Using temperature sensors and monitoring systems can help detect early signs of failure, allowing for proactive replacement.

Custom Solutions

Work with your heater manufacturer to design custom solutions tailored to your specific application requirements. Custom heaters can be optimized for fit, watt density, distributed wattage, and environmental conditions, leading to improved performance and longevity.

By understanding the factors that impact the longevity of cartridge heaters and considering strategic changes, you can significantly extend the operational life of these crucial components. Whether it’s selecting the right materials, improving installation practices, or investing in advanced design features, each step contributes to enhanced performance and reliability. At Backer Marathon, we’re dedicated to providing high-quality cartridge heaters and expert guidance to help you achieve optimal results in your packaging and plastic processing applications. For more information or to discuss your specific needs, contact our team today.

Helping OEMs Heat Up

Backer Marathon is the industry leader in production speed and reliable, quality heaters for plastics and packaging, serving OEMs with durable, customized solutions for unique heating needs. Backer Marathon designs, manufactures, and stocks industrial-grade heating elements and temperature sensors.

Engineers have direct access to our trained technical experts who have been pioneers in this sector for decades. Our vast array of heaters serves diverse industries and applications—from food and beverage packaging to industrial platens used in compression molders.

We believe in hard work, creative engineering, and excellent customer service. Whether you need one piece or one thousand, Backer Marathon is committed to providing you with exactly what you need when you need it. As we innovate and lead the industry with unparalleled engineering and customer service, we look forward to helping you continue to grow with us. Let’s talk about your next project. Contact us now or call us today at 1 (830) 775-1417. We’re excited to collaborate with you. Hablamos Español, tambien.